Introduction

The kitchen and plumbing in my campervan is very important for making the van feel like a home. I decided to go with a reasonably sized water tank and a fully electric pumping system. I went as cheap as I could and avoided the costly Dometic equipment (an Ikea sink is just fine!) I have included links on the items I used below to allow future vanlifers to find the needed equipment easier, and better research the items I used.

Materials used

Plumbing

- Barker Manufacturing Company 11915 15 Gal. Water Tank Kit ($105.87 on Amazon)

- Duda Energy HPpvc050-010ft 10' x 1/2" ID High Pressure Braided Clear Flexible PVC Tubing ($12.05 on Amazon)

- SHURFLO 4008-101-E65 3.0 Revolution Water Pump ($70.12 on Amazon)

- SHURFLO (255-313) 1/2" Twist-On Pipe Strainer ($8.11 on Amazon)

- SHURFLO Black 182-200 Accumulator Tank ($35.60 on Amazon; have not installed yet and still deciding if it's really needed)

- 90 degree Straight fittings 1/2 fpt x 1/2 barb with wings ($6.60 on Amazon)

- LASCO 13-1815 Test Plugs for Copper with Wing Nut for 1-Inch Inner Diameter ($8.80 on Amazon)

- IPOW Solid Brass Body Backyard 2 Way Y Valve Garden Hose Connector Splitter Adapter ($11.99 on Amazon)

- Dixon DGH7 Brass Quick-Connect Fitting, Garden Hose Complete Set, 200 psi Pressure ($11.15 on Amazon)

- Camco Flexible Camper Drain 37420 ($10.63 on Amazon)

- Reliance Products Aqua-Tainer 4 Gallon Rigid Water Container ($17.28 on Amazon)

- Apex, 883-6, Hose Reel Leader Hose for Reels with Male Connector, 5/8-Inch x 6-Feet ($11.99 on Amazon; for drainage)

- 25' Long Potable Grade Water Hose for Filling Tank ($18.99 at McLendon Hardware)

Kitchen

- 4' Long Vinyl Counter-top ($50 at Lowes)

- Fyndig Stainless Steel Oval Sink ($50 at Ikea)

- Lagan Single Lever Kitchen Faucet 6.25" Height ($24.99 at Ikea)

- Sink Strainer and Stopper ($10 at Ikea)

- Bass Pro Shops two burner portable propane stove (Free from Alaska fishing contest prize)

Wood for Cabinetry (Excluding Refrigerator)

- Ten (10) 2" X 3" X 8' Long Spruce Studs ($2.09 each at Home Depot)

- Extra pine panels (Purchased Earlier)

- Extra pieces of 1/2" and 3/4" plyood for cabinet partitions (Free from my dad)

- 4' X 4' piece of 1/4" MDF hardboard with white top ($15 at Home Depot)

- 12' long 1" X 4" oak board (Purchased Earlier)

- 4' long 1" X 6" oak board ($10 at Lowes)

- 12' long 1" X 2" oak board ($12.99 at Lowes)

- 6' long by 9.5" wide and 1/2" thick Jatoba board ($79 at Crosscut Lumber)

- 30" long by 9.5" wide and 1/2" thick replacement piece of Jatoba since first piece from Crosscut was too warped on one end ($20 at Austin Hardwoods)

Hardware

- Three (3) Bronze finished cabinet handles ($3.78 each at Lowes)

- Two (2) pairs of 14" long drawer slides ($16 each at Home Depot)

- Box of 2.5 inch Kreg Pocket hole screws ($6.99 from Lowes)

- Eight (8) 90 degree angle brackets ($2.99 each at Lowes)

- Four (4) Liberty Brand soft close Inlay Cabinet Hinges ($5.18 each at Home Depot)

- Leisure Products (PM 2001 L 40 lbs 90 Degree Magnetic Mount Catch (16.47 on Amazon)

- Teflon Tape (Free from my dad)

- Various Sized Pipe Clamps (Free from my dad)

- Barker Manufacturing Company 11915 15 Gal. Water Tank Kit ($105.87 on Amazon)

- Duda Energy HPpvc050-010ft 10' x 1/2" ID High Pressure Braided Clear Flexible PVC Tubing ($12.05 on Amazon)

- SHURFLO 4008-101-E65 3.0 Revolution Water Pump ($70.12 on Amazon)

- SHURFLO (255-313) 1/2" Twist-On Pipe Strainer ($8.11 on Amazon)

- SHURFLO Black 182-200 Accumulator Tank ($35.60 on Amazon; have not installed yet and still deciding if it's really needed)

- 90 degree Straight fittings 1/2 fpt x 1/2 barb with wings ($6.60 on Amazon)

- LASCO 13-1815 Test Plugs for Copper with Wing Nut for 1-Inch Inner Diameter ($8.80 on Amazon)

- IPOW Solid Brass Body Backyard 2 Way Y Valve Garden Hose Connector Splitter Adapter ($11.99 on Amazon)

- Dixon DGH7 Brass Quick-Connect Fitting, Garden Hose Complete Set, 200 psi Pressure ($11.15 on Amazon)

- Camco Flexible Camper Drain 37420 ($10.63 on Amazon)

- Reliance Products Aqua-Tainer 4 Gallon Rigid Water Container ($17.28 on Amazon)

- Apex, 883-6, Hose Reel Leader Hose for Reels with Male Connector, 5/8-Inch x 6-Feet ($11.99 on Amazon; for drainage)

- 25' Long Potable Grade Water Hose for Filling Tank ($18.99 at McLendon Hardware)

Kitchen

- 4' Long Vinyl Counter-top ($50 at Lowes)

- Fyndig Stainless Steel Oval Sink ($50 at Ikea)

- Lagan Single Lever Kitchen Faucet 6.25" Height ($24.99 at Ikea)

- Sink Strainer and Stopper ($10 at Ikea)

- Bass Pro Shops two burner portable propane stove (Free from Alaska fishing contest prize)

Wood for Cabinetry (Excluding Refrigerator)

- Ten (10) 2" X 3" X 8' Long Spruce Studs ($2.09 each at Home Depot)

- Extra pine panels (Purchased Earlier)

- Extra pieces of 1/2" and 3/4" plyood for cabinet partitions (Free from my dad)

- 4' X 4' piece of 1/4" MDF hardboard with white top ($15 at Home Depot)

- 12' long 1" X 4" oak board (Purchased Earlier)

- 4' long 1" X 6" oak board ($10 at Lowes)

- 12' long 1" X 2" oak board ($12.99 at Lowes)

- 6' long by 9.5" wide and 1/2" thick Jatoba board ($79 at Crosscut Lumber)

- 30" long by 9.5" wide and 1/2" thick replacement piece of Jatoba since first piece from Crosscut was too warped on one end ($20 at Austin Hardwoods)

Hardware

- Three (3) Bronze finished cabinet handles ($3.78 each at Lowes)

- Two (2) pairs of 14" long drawer slides ($16 each at Home Depot)

- Box of 2.5 inch Kreg Pocket hole screws ($6.99 from Lowes)

- Eight (8) 90 degree angle brackets ($2.99 each at Lowes)

- Four (4) Liberty Brand soft close Inlay Cabinet Hinges ($5.18 each at Home Depot)

- Leisure Products (PM 2001 L 40 lbs 90 Degree Magnetic Mount Catch (16.47 on Amazon)

- Teflon Tape (Free from my dad)

- Various Sized Pipe Clamps (Free from my dad)

Total Material Cost: $700 US Dollars (Does not include tools purchased)

Tools Used

- Drill with Assorted Bits and Drives

- Measuring Tape

- Carpenters Square

- Manual Screwdrivers

- Jig Saw

- Table Saw

- Sockets

- Wrenches

- Measuring Tape

- Carpenters Square

- Manual Screwdrivers

- Jig Saw

- Table Saw

- Sockets

- Wrenches

step 1 - install the tank and pump

May 2018

With any campervan, you must decide whether or not you want running water. I decided it was worth having, and wouldn't bee too challenging to implement. I had already predetermined where I was going to store the water tank, and I built the couch to perfectly fit a 12" by 12" by 24"water tank, which I bought on Amazon. The tank came with pre-made holes for a drain, fill hole, air vent, and outflow. I also had to buy a water pump, and after some research I decided to get the tried and true SHURFLOW 3.0 gallons/minute, 55PSI water pump. This is the perfect size, because it won't empty the tank too fast (if left running constantly, it will take 5 minutes to empty the tank). This is perfect for simple tasks like quickly rinsing dishes, brushing teeth, or filling pots for cooking.

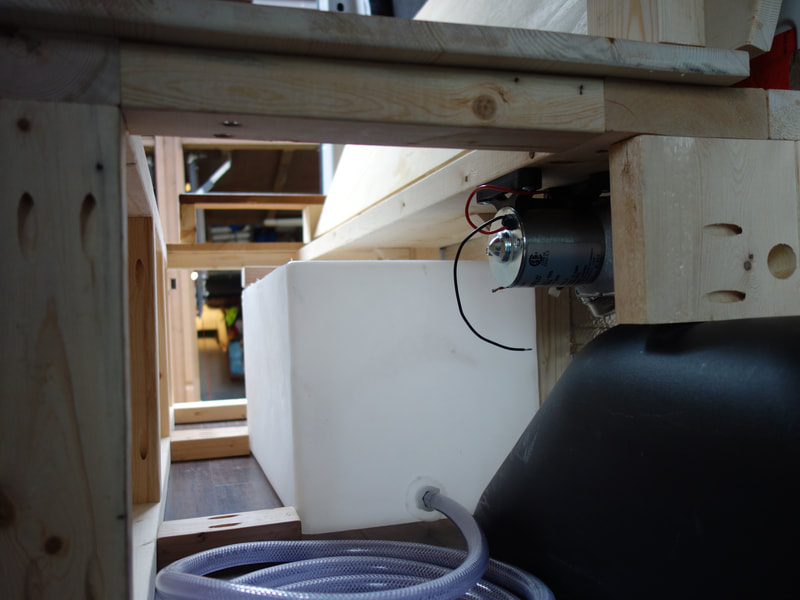

First, I cleared a spot for the water tank under the couch, and secured it in place to prevent it from sliding around with extra short pieces of 2" X 3" studs attached to the existing couch frame. I used the Kreg jig to securely attach them, along all sides of the tank, as well as above it to keep it from bouncing upwards in the event of a large bump on the road. Next, I located a spot on the underside of the horizontal beam that comprises the bottom of the couch to place the water pump. This spot is very close to the tank, allowing for least amount of distance as possible to maximize the pump performance. Because the pump can be mounted in any orientation, this gave me quite a bit of freedom of where to place it. I also purchased the pump strainer designed for this SHURFLOW pump, and it was an easy screw connection on the inflow side of the pump. The tank came with 1/2" threaded fittings with barbed nozzle ends for a water tight seal against the braided hose. These were easily screwed into the pre-fabricated threaded holes in the tank, with some Teflon tape for added seals. It is important not to screw these on too tight because the treads are only plastic! With the barbed fittings screwed onto the tank, I used the 1/2" flexible braided hose, and cut a piece to connect the outflow port of the tank to the pump strainer, pushing the hose over the barbed fittings and clamping with 3/4" pipe clamps. I then ran the electrical wiring from the pump to the fusebox, including a switch to allow for the pump to be completely off when not needed. This is all described in more detail in my electrical system article.

First, I cleared a spot for the water tank under the couch, and secured it in place to prevent it from sliding around with extra short pieces of 2" X 3" studs attached to the existing couch frame. I used the Kreg jig to securely attach them, along all sides of the tank, as well as above it to keep it from bouncing upwards in the event of a large bump on the road. Next, I located a spot on the underside of the horizontal beam that comprises the bottom of the couch to place the water pump. This spot is very close to the tank, allowing for least amount of distance as possible to maximize the pump performance. Because the pump can be mounted in any orientation, this gave me quite a bit of freedom of where to place it. I also purchased the pump strainer designed for this SHURFLOW pump, and it was an easy screw connection on the inflow side of the pump. The tank came with 1/2" threaded fittings with barbed nozzle ends for a water tight seal against the braided hose. These were easily screwed into the pre-fabricated threaded holes in the tank, with some Teflon tape for added seals. It is important not to screw these on too tight because the treads are only plastic! With the barbed fittings screwed onto the tank, I used the 1/2" flexible braided hose, and cut a piece to connect the outflow port of the tank to the pump strainer, pushing the hose over the barbed fittings and clamping with 3/4" pipe clamps. I then ran the electrical wiring from the pump to the fusebox, including a switch to allow for the pump to be completely off when not needed. This is all described in more detail in my electrical system article.

step 2 - build the counter-top Framework

August 2018

Once the water pump and water tank were securely mounted, and the short 3' hose connecting them was secured and sealed, I drilled a 1" hole with a spade bit through the couch frame directly above the wheel well for the outflow hose to fit through, that will eventually get connected to the faucet once the sink and counter was built. In the photo directly above on the left side, there is a hole on the far right edge just above the wheel well. This is where the outflow hose will be routed. I cut the hose longer than I knew I'd need, and pushed it through the hole and connected it to the outflow valve of the water pump.

A number of months passed before I got the time to build the frame for the counter-top and install the sink and faucet. In the meantime after the tank and pump were installed, I built the electrical closet and pantry directly adjacent to the couch (see next articles). In early October 2018 I was able to build the kitchen counter, and started by securing a long piece of 2" X 3" stud along the length of the side van wall with the rivet nuts. This piece would act as a perfect anchor for most of the frame. I built down and out from here, precisely measuring additional pieces of 2" X 3" to make a solid and square frame that extended out enough to allow the final Cherry (Jatoba) facial boards to be flush with the electrical closet. I had to make extra sure the top of the frame where the counter-top with sit on was perfectly flat and square, so I added wood glue to these joints and clamped in place. In the first photo below, notice the finished electrical closet (bottom) and pantry (top) on the left edge, with the outflow hose sticking through. With the frame complete, I was now able to install the counter-top and sink.

A number of months passed before I got the time to build the frame for the counter-top and install the sink and faucet. In the meantime after the tank and pump were installed, I built the electrical closet and pantry directly adjacent to the couch (see next articles). In early October 2018 I was able to build the kitchen counter, and started by securing a long piece of 2" X 3" stud along the length of the side van wall with the rivet nuts. This piece would act as a perfect anchor for most of the frame. I built down and out from here, precisely measuring additional pieces of 2" X 3" to make a solid and square frame that extended out enough to allow the final Cherry (Jatoba) facial boards to be flush with the electrical closet. I had to make extra sure the top of the frame where the counter-top with sit on was perfectly flat and square, so I added wood glue to these joints and clamped in place. In the first photo below, notice the finished electrical closet (bottom) and pantry (top) on the left edge, with the outflow hose sticking through. With the frame complete, I was now able to install the counter-top and sink.

step 3 - install counter-top and sink

August 2018

Using the 4' long piece of pre-fabricated vinyl counter I purchased on the cheap at Lowes, I had to first rip it down to the width needed. The counter came with a built in backsplash, and was an industry standard of about 25" wide. My frame was only about 19" wide, so I used the table saw to cut 6" off the backside, including the non-essential backsplash. I followed the instructions that came with the Ikea sink and marked exactly where I would need to cut the hole for the sink to sit flush with the counter. I decided to center it, rather than offset it. Using a jig saw, I slowly cut out the required shape and test fit the finished counter-top and sink assembly atop the framework. Everything seemed to fit well, so I secured the counter-top to the frame with 90 degree angle metal furniture braces from the underside. Securing the sink to the counter-top involved messing around a lot with the hardware that was included with the sink, but with enough tinkering, I managed to get it to work. Apparently these are standard pieces of hardware that anyone who has worked with sinks before will know how to use, however this was the first sink I've ever installed, so it took a while to figure out.

The last thing to do was to drill the hole through the counter for the faucet, which was an easy ordeal using a hole saw. I just had to make sure to place the faucet in a spot where the triangular plastic washer that is placed on the underside has a spot to be perfectly flush against the counter without hitting a frame board or the sink. The left corner ended up being the best place. Once the faucet was installed and tightened, I plugged the hot side with a threaded brass plug (since I will only be using cold water) and attached the outflow hose to the cold side of the faucet. This involved cutting the hose to length, and using U shaped brackets to secure it to the frame so it wouldn't jolt around when the water is turned on and off.

The last thing to do was to drill the hole through the counter for the faucet, which was an easy ordeal using a hole saw. I just had to make sure to place the faucet in a spot where the triangular plastic washer that is placed on the underside has a spot to be perfectly flush against the counter without hitting a frame board or the sink. The left corner ended up being the best place. Once the faucet was installed and tightened, I plugged the hot side with a threaded brass plug (since I will only be using cold water) and attached the outflow hose to the cold side of the faucet. This involved cutting the hose to length, and using U shaped brackets to secure it to the frame so it wouldn't jolt around when the water is turned on and off.

Step 4 - build the drainage system

February 2020

Before I could even think about testing the whole system, I had to have a proper drainage solution. I decided I would have both a grey water tank on board stored underneath the sink, as well as a direct through-the-floor drain. This would allow me to utilize the grey water tank when I needed to be environmentally conscious, or simply drain through the floor when just water was draining out, and would not have an effect on the environment. There was over a year hiatus between getting the countertop installed and completing the whole drainage system due to various travels, climbing trips, and work trips throughout 2019, which proved to be an insanely busy year for me. Before I could begin the drainage system, I had to lay out how the entire space below the countertop was going to be used, decide on a refrigerator to use, and which size grey water tank to use. I purchased a 4 gallon grey water tank and decided on an Engel top door cooler (see refrigerator article). With these decisions made, I started building the interior of the kitchen cabinetry. The grey water tank I bought is a Reliance Aqua-Tainer 4 gallon size with a cubic shape, which I placed on the bottom right side of the space directly on the floor, then build a guard around it to keep it from sliding. I utilized most of the fittings and piping outlined in the faroutride model on their website here, which explains in incredible detail their water system. They were extremely helpful detailing which exact pieces of hardware and equipment are needed for this setup. Essentially, I got a short piece of garden hose with a Y valve to split the drainage flow, a quick release for disconnecting the hose from the tank, and the drain bowl with flexible hose that screwed into the bottom of the sink. With the tank secured and drainage piping connecting it to the sink, I then used a hole saw to cut a small hole through the floor, just a tiny bit larger than the OD of the garden hose, and added a second drainhose to the other port on the Y valve. This way I can switch the valves and have drainage water either go into the tank or through the floor. Lastly, I secured all these hoses with small clamps.

step 5 - build kitchen cabinetry and drawers

I then started building out drawers on the upper portion of the space on the right and left sides of the sink, and custom cut a piece of 1/4" MDF board to fit horizontally in the middle, effectively dividing the space into two sections. I added pieces of 2" X 3" studs adjacent to the sides of the sink that would hold the drawer slides. The large area at the bottom would hold the refrigerator in addition to the grey water tank, where the area in the middle I built to hold kitchen supplies, and a portable stove that I had from winning a fishing contest years ago. I glued on the front edges of the cabinet pieces of 1" X 2" oak that I stained for a nice finish, and secured the interior cabinet walls with angle brackets. Nothing fancy, but it works well. I used the table saw to make the drawer boxes and cut a 1/4" dato on the bottom inside edges of each piece for the MDF board to slip into, then with the Kreg tool jig, drilled and screwed them all together with glue. It was very important to cut the drawer box pieces to the exact correct size, and ensure everything was square. Each drawer slide is 1/2" thick, so my drawer box needed to be exactly 1" narrower than the drawer box opening. The depth of the drawer I made as large as possible without hitting anything behind along the metal van panel (insulation, electrical wires etc). I finished the drawers with a facial oak 1" X 6" board and grab handles.

step 6 - build the doors

Next, I built the door that would cover the central part of the cabinet (shown open in the photo just above and right). I built it the same way I build most of the other doors with oak 1" X 4" around with the pine paneling in the center. I again custom build tongue and grooves, as well as a dato in the oak boards for them to completely encircle the pine boards that would inset. I glued the oak pieces together, sanded and routed the edges and stained it all before installing the hinges and mounting it to the face of the cabinet. The 90 degree manget brackets hole it closed. A second door was made using the Jatoba redwood that would open to the right to reveal the grey water tank. I built this the same way I made the other Jatoba doors, using a couple pieces of 1" X 2" oak secured to the back of each piece to stack them to get the full height I needed. I left a nominal 1/4" gap between them to match the gaps I had from other parts of the build. The same inset cabinet hinges were used to mount the door to the frame, and another 90 degree magnet holds it shut.

Proudly powered by Weebly